- Home Page

- Company Profile

-

Our Products

- Led X-Ray Viewer

- View Box

- LED X-Ray Film View Boxes

- Triple Screen High LED X-Ray Viewer

- Four Screen High LED X-Ray Viewer

- X- Ray Viewing

- Single Screen High End LED X-Ray Viewer

- Multi-Function LED X-Ray Viewer

- Highly Efficient Double Screen LED X-Ray Viewer

- X Ray Viewer

- Slim Led View Box

- Advance LED X-Ray illuminator Viewing Box

- X Ray Film Viewer

- LED Film Viewer

- LED X-RAY FILM VIEWER

- Led X Ray Film Viewer Having No Uv Emissions

- Slim Led X Ray View Box

- Six Screen Le D X Ray Viewer

- One Screen X - Ray Viewer

- X Ray View Box for Hospital

- Triple Screen X Ray Viewer

- LED X Ray Viewer

- X Ray Illuminate Film Box

- X Ray Film View Box

- X-Ray View Box with Double Film

- Digital X-Ray Film

- Bio X XRay Illuminator

- X Ray Film Viewing Panel

- X Ray Viewing Screen

- LED X-ray Viewer With Automatic Shutdown Mechanism

- Slim, Durable and Effective Six Screen LED X-Ray Viewer for Sale

- Four Screen LED XRay Viewer with Long Service Life

- Durable and Effective LED X-ray Viewer by a Leading Exporter

- Perfect Finishing X- Ray Viewer Available for Hospitals

- Factory Supply of Single Screen LED X-Ray Film Viewer at Considerable Rate

- Best Manufactured Four Screen LED X-Ray Viewer with Long Service Life

- Industrial LED X Ray Film Viewer with Different Screen Option

- X Ray Film Viewer with Unparalleled Latest LED Technology

- Energy Efficient LED X Ray Film Viewer

- X Ray View Boxes

- Slim ,Durable and Effective Triple LED X-Ray View Box Available for Sale

- Four Screen X-Ray Film Viewer

- Two Screen X Ray Viewer

- LED X-Ray Film Viewer with Long Lasting Structure

- Viewing Box

- Easily Dimmed Single Screen LED X-Ray Film Viewer

- Highly Efficient Double Screen LED X-Ray Viewer with Best Specification

- LED X-Ray View Box with Digital Dimmer

- LED X-ray View Box with Automatic Shutdown Mechanism Available for Sale

- 100% Safe Result Oriented LED X-ray Viewer

- LED X-Ray View Box with Double Film

- Film Viewer Flush Mounted

- Light Weight X Ray View Box

- Double Screen Led X Ray Viewer

- Cost Effective LED X-Ray Film Viewer with Slient and Easy Operation

- Double Screen X Ray Viewer

- Flush Mounted LED X-Ray Film Viewer

- Most Recommended Triple Screen X-RAY Film Viewer Available at Attractive Price

- Ultra Slim X- Ray View Box

- LED X Ray Film Box

- X Ray Film Illuminator

- Single Screen X Ray Viewer

- Triple LED X Ray Medical View Box , X-Ray Film Viewer , X-Ray Viewing Box at Cheap Price

- Led X Ray Viewer

- Flush Mounted Led X- ray Viewer

- Lcd X-Ray Film Viewer

- LED X- Ray Film Viewer from Certified Manufacturer for Hospital Use

- L.E.D X Ray Illuminator

- X-Ray Film Viewer

- X Ray Illuminators

- Economy Version Single Screen

- Triple Screen Led X Ray Viewer

- Economy Version Double Screen

- Single Screen Led X Ray Viewer

- Led X Ray View Box

- Six Screen LED X-Ray Viewer

- Triple LED X-Ray View Box with Digital Dimmer Technology

- Multi-Function FourScreen LED X-Ray Viewer from Top Manufacturer

- LED X-Ray Viewer

- CE Marked Ultra Slim LED X-Ray View Box Available at Amazing Price

- Economy Screen With Power Adaptor

- LED X Ray View Box

- Ultra Slim And Light X Ray View Box

- X Ray View Box

- X-Ray View Boxes

- High End X-Ray Film Viewer

- Slim LED X- Ray Film Viewer

- Slim X Ray View Box

- Professional Design LED X-ray View Box Available at Best Selling Market Rate

- Three Screens X Ray Viewer

- X - Ray Film Viewers

- Triple Screen Flush mounted

- Double Screen High End LED X-Ray Viewer

- Patient Identification Bands

- ID Bands for Children

- Patient Identification Wristband

- Pediatric Write On Vinyl

- Pediatric Bands

- Adult Patients Id Wristbands Available from Certified Supplier

- Events Wrist Bands

- ID Bands for Adult

- Adult Insert Card White

- Patient Idenification Bands

- Mother And Baby Insert Cards

- Mother-Baby Id Bands

- Pediatric ID Band

- Patient Identification band

- Insert Card Bands

- Adult Insert Card Bands (pink)

- Patient ID Bands

- Patient Identification Wristbands

- Patient Wrist Bands

- Medical Wrist Bands

- Patient Armbands

- Allergy Allert Bands

- Adult Insert Card Bands - Patient Identification Bands

- Write-on Wristbands

- Mother Infant Wristbands

- Wrist Id Bands

- Patient Wrist Band

- Write On Wristbands

- Baby Bracelet Blue

- Adult Insert Card Band

- Mother Baby Bands

- Pediatric Id Bands

- Identification Bands

- Soft Vinyl Mother-Infant Wristbands with Insert Card

- Insert Card Wristbands

- Adult Insert Card

- Mother-Infant Wristbands with Snap Closure Available at Best Selling Price

- Patient Identification Band

- Adult Bracelet ID Bands

- Patient Identification Bands For Hospital

- Mother Baby Identification Band

- Patient ID Systems

- Pediatric Identification Band

- Patient ID Wrist Bands

- Standard Grade Adult Plastic Material Write On Bands for Sale

- Paitent Id Bands

- Patient Bracelet

- Barcoding

- Patient Identification Bracelets

- Hospital Bands

- Bands for Hospital

- Patient Identificaion Bands

- Wristbands

- Wrist Bands For Events

- Surgeon Control Panel

- Surgeon Information Display

- User Friendly Surgeon Control Panel with Medical Gas Alarm

- Touchglass Surgeon Control Panel

- Hospital Use Advanced Digital Surgeon Control Panel at Lowest Rate

- Surgeon Control Panel- Touch Screen (Membrane Type)

- Surgeon Control Panel- Membrane Type

- High Rating Surgeon Control Panel Available at Affordable Price

- Surgeon Control Panel with Temperature Indicator for Sale

- Membrane Type, Touch Screen Type Surgeon Control Panel

- Most Advance User Friendly Membrane Type Surgeon Control Panel

- Membrane type Surgeon Control Panel with Medical Gas Alarm System

- CE Marked Surgeon Control Panel from Certified Manufacturer

- Temperature Indicating Surgeon Control Panel with Large Display

- Easy Operating Surgeon Control Panel With Touch Screen

- Wide Range of Surgeon Control Panel for Medical Console

- Professional Grade Surgeon Control Panel with Touch Sensitive Monitor at Low Price

- Surgeon Control Panel with Monochromatic Graphic Touch Screen Panels

- Surgeon Control Panel

- Surgeon Control Panel with Temperature and Humidity Indicator

- High Rating Surgeon Control Panel with Extra Features

- Control Panel For Modular Operation Theatre

- Modular Operation Theater Control Panel (Membrane Type)

- Operation Theatre Control Panel (Membrane Type)

- Control Panel (Membrane Type)

- 4 Tile Surgeon Control

- Temperature And Humidity Control - Surgeon Control

- Automatic Shoe Cover Dispenser

- Automatic Shoe Lamination Machine

- Shoe Cover Wrapping Machine

- Aluminium Automatic Shoe Cover Dispenser

- Long Lasting Shoe Cover Dispenser with Quick Functioning

- Automatic Grade Shoe Cover Dispenser for Clean Rooms

- Strong And Steady Shoe Cover Dispenser With Automatic Functioning

- Shoe Cover Machine

- Superior Quality Shoe Cover Dispenser Available with Optimum Performance

- More Efficient And Convenient Shoe Cover Dispenser

- Automatic Shoe Cover Dispenser For Pharmaceutical And Chemical Industries

- Strong And Steady Performence Oriented Automatic Shoe Cover Dispenser

- Hospital Shoe Cover Dispenser

- Shoe Cover Dispenser

- Aluminium Alloy Made Automatic Shoe Cover Dispenser

- Shoe Cover Dispensers for Hospital

- Efficient and Convenient Automatic Shoe Cover Dispenser at Attractive Price

- Automatic Shoe Cover Dispenser

- Shoe Cover Dispenser to Automatically Wrap Shoe in Hospitals Available

- Excellent Appearance Metallic Silver Body Shoe Cover Dispenser Available for Sale

- Factory Direct Sale of Latest Automatic Shoe Cover Dispenser

- Shoe Cover Dispenser Machine

- Metallic Silver Body Shoe Cover Dispenser for Office and Hospital Use

- Hot Selling Shoe Cover Dispenser Available at Best Price

- Shoe Cover Dispenser Available at Amazing Price for Bio-Engineering Industry

- Strong Durable Shoe Cover Dispenser Available for Food Industry (1)

- Premium Quality Top Selling Shoe Cover Dispenser for Multiple Use

- Aluminium Alloy Shoe Cover Dispenser

- Evacuated Blood Collection Tube

- Vacuum Blood Collection Tube

- Double Cap Sodium Citrate Vacuum Blood Collection Tubes

- High Quality Disposable Vacuum Tube for Blood Collection Available at Affordable Price

- Vaccum Blood Collection Tube

- Vacuum Tubes

- Sodium Citrate Tube(1.9) Vacuum Blood Collection Tube

- Wholesale Selling of Colour Coded Vacuum Blood Collection Tube

- Highly Recommended Disposable Vacuum Blood Collection Tube

- Superior Grade Best Selling Vacuum Blood Collection Tubes for Hospital Use

- ESR Sodium Fluoride Vacuum Blood Collection Tube

- Excellent Quality Medical Grade Vacuum Blood Collection Tube Available for Bulk Buyers

- Vacuum Blood Collection Tube From Shandong

- Excellent Quality CE Certified Vacuum Blood Collection Tube

- High Quality Medical Grade Needle Available at Low Price

- CE Approved Vacuum Blood Collection Test Tube for Medical Use

- Heparin Vacuum Blood Collection Tube Available at Affordable Rate

- High Quality Vacuum Blood Collection Tube Available for Sale

- Plain Tubes

- Gel & Clot Activator Vacuum Blood Collection Tube

- Sodium Citrate Vacuum Blood Collection Tube

- Vacuum Blood Collection Tube for Laboratory Use Available at Best Price

- EDTA Tubes

- Excellent Quality Vacuum Blood Collection Tube from Top Rated Manufacturer

- PRP Tubes

- Evacuated Blood Collection Tube

- Ceiso Approved High Quality Vacuum Blood Collection Tube For Sale

- CE Approved Vacuum Tubes for Blood Collection Available at Market Price

- Evacuated Blood Collection System

- Laboratory Single Use Plastic Material Vacuum Blood Collection Tubes for Sale

- Highly Tested Clean Vacuum Blood Collection Tube at Affordable Rate

- Medical Disposable Vacuum Blood Collection Tube For Test Available For Bulk Purchase

- Blood Collection Needles

- Single Use Blood Collection Tube Available at Bulk Rate

- High Quality Disposable Vacuum Blood Collection Tube for Lab Use

- Sodium Fluoride And Potassium Oxalate

- Edta K3

- Blood Tubes

- Blood Collection Tubes

- Blood Collection Tube

- Citrate Tubes

- Glucose Tubes

- Clean Room Mats

- Medical Antimicrobial Floor Mats

- Antimicrobial Mat

- Multilayer Mat

- Adhesive Sticky Mat

- MULTIMAT

- Dust Control Sticky Mats

- Antimicrobial Mat Medical Floor Mat for Sale

- Multiple Layer Adhesive Blue Coloured Film Anti-Slip Mat Available for Clean Rooms

- High Quality Clean Room Mat Available for Hospital Use

- Antifungal Mat

- Multimat

- Hospital Sticky Mat

- Antimicrobial Floor Mats

- Clean Room Sticky Mat

- Antibacterial Sticky Mat

- Patient Transfer System

- Hospital Easy Move

- Patient Transfer Bed

- Patient Transfer Systems

- Strong Light Weight Easy To Use Patient Transfer Sheer

- Patient Transfer Sheet

- PTS PATIENT TRANSFER SYSTEM

- Easy Move Patient Transfer System

- Patient Transfer

- Patient Transfer Sheet Manufactured From Unbreakable Plastic

- Easy Move Disposable Patient Bed Transfer Sheets

- Patient Transfer System

- Patient Transfer Slide Board

- Patient Transfer Board

- Patient transfer Device

- High Quality Medical Patient Transfer Boards Sheet for Sale

- Foundry Alloys & Chemicals

- Refurbished Industrial Centrifuge Machine SUKHRAS

- Zinc Flux

- Aluminium Strontium 10%

- Boron Hardener

- Aluminium Powder

- Boron Nitrate Coating

- Logas - 2b Copper Degasser

- Magnesium Chloride (Anhydrous)

- Coil Feeder Machine

- Scot Deoxidising Tubes Cb3

- Copper Addition Tablet

- Copper Flux

- Deoxidizing Tubes

- Highly Pure Hexachloroethane

- Perchloroethylene

- Potassium Aluminium Fluoride

- Potassium Fluoborate

- Potassium Silico Fluoride

- Potassium Titanium Fluoride

- Silicon Carbide Crucible Resign Bonded

- Sodium Silico Floride SSF

- Flux For Rotary Furnace

- Karnalite

- Logas - 1a Copper Degasser

- Porosity Meter Hydrogen Testing Machine

- Foundry Chemicals

- Degasser 200

- Degasser N2 (Nitrogen Based)

- Nucleant 2 (Grain Refiner)

- Lomag (Magnesium Remover)

- Cover Flux

- Granulated Fluxes

- Ceramic Foam Filters Made with Superior Quality Raw Materials

- Aluminum Strontium

- Robust Structure Ceramic Foam Filters

- Aluminum Titanium Boron (Grain Refiner) Alti5b1 Coils S

- Quality Material Made Ceramic Foam Filters Available at Affordable Rate

- Aluminum Titanium Boron Coils

- Robust Structure Ceramic Foam Filters with 100% Accurate Dimension

- New Technology Manufactured Ceramic Foam Filters

- Manganese Tablet

- Hot Selling Ceramic Foam Filters with Low Bulk Density

- Flux Injection Machine

- Silicon Metal

- Die Lube

- Shapes Launders Foundry Chemical

- Hot Selling Hexachloroethane with 99% Purity

- White Hexachloroethane Powder

- Certified Quality Ceramic Foam Filters with Good Purifying Efficiency

- High Performance Ceramic Foam Filters at Affordable Rate (1)

- Widely Demanded Ceramic Foam Filters from Trusted Market Supplier

- Best Selling Absorptive Ceramic Foam Filters at Low Rate

- Fine Finish Good Quality Shapes

- Shapes for Metal Casting Industries

- High Performance Long Lasting Ceramic Foam Filters

- Superior Exclusive Range of Insural Shapes

- Hexachloroethane FLUX Available for Sale

- White Powder Hexachloroethane

- Non-Flamable Solid Hexachlorethane Available at Bulk Rate

- Best Quality Hexachloroethane from Wholesale Supplier

- Premium Grade Hexachloroethane Flux Available at Wholesale Price

- Ceramic Foam Filters for Marbles

- Ceramic Foam Filters

- Highly Appreciated and Accurate Ceramic Foam Filters for Sale

- Certified Ceramic Foam Filter For Casting With Higher Efficiency

- Robust Structure Ceramic Foam Filter for Metal Filtration

- Standard Competitive Price Customized Shape Ceramic Foam Filter for Large-Scale Used

- Ceramic Foam Filter

- Effective Ceramic Foam Filters made from Superior Quality Raw Material Available for Sale

- Blood & Fluid Warmers

- Fogger Machine

- Patient Transfer Slide Sheet

- Hot Selling Patient Transfer Slide Sheets for Sale

- Easy to Use Patient Transfer Sheet

- Simple To Use Cost Effective Plastic Patient Transfer Sheet For Sale

- Easy To Carry Comfortable Patient Transfer Sheet Available At Amazing Price

- Easy to Slide Patient Transfer Slide Sheets Available in Various Colours

- Unbreakable Plastic Made Patient Transfer Sheet

- Operating Room Comfortable Foldable Patient Transfer Sheets

- Cost Effective and Light Weight Patient Transfer Sheet for Sale

- Pet Strapping Machines

- Modular Operation Theater Equipments

- Medical Grade Monitor

- Medical Grade Monitor- 19 inch

- Medical Grade Monitor- 24 Inch

- LED X-Ray View Box

- Blood And Fluid Warmer

- Modular Operation Theatre

- Medical Grade Monitor- 32 Inch

- Medical Grade Monitor- 27 inch

- Medical Grade Monitor- 55 Inch

- LG Medical Grade Monitor 19HK312C-B

- LG Medical Grade Monitor 27HQ710S

- LG Medical Grade Monitor 55MH5K

- LG Medical Grade Monitor 27HK510S

- LG Medical Grade Monitor 32HL710S

- LG Medical Grade Monitor 32HL714S

- Grade Monitor

- REFURBISHED GE CT/E SINGLE CT MACHINE

- MRI Compatible Products

- MRI Compatible Ear Plug

- MRI Compatible Fire Extinguisher

- MRI Compatible Ferromagnetic Detector

- Video Bronchoscope Reusable

- Mri Compatible Trolley/ Stretcher

- MRI Compatible IV Pole

- VIDEO BRONCHOSCOPE

- MRI Compatible Pulse Oximeter

- MRI Compatible Sound System

- MRI Compatible Anaesthesia Machine

- MRI Compatible Cinema System

- Hand Held MRI Metal Detector

- MRI Compatible LED Monitor

- MRI Compatible FMRI Systems

- MRI Compatible Emergency Cart

- MRI Compatible Sphygmomanometer

- Video Laryngoscope

- MRI Compatible Video Laryngoscopes

- MRI Compatible Stethoscope

- MRI Compatible ECG Electrodes

- MRI Compatible Wheelchair

- REFURBISHED GE BRIGHT SPEED 4/8/16 CT MACHINE

- Air Decontamination System

- MRI Compatible Ear Muff

- Video Bronchoscope Disposable

- MRI HEARING PROTECTORS NEWBORN Minimuffs

- REFURBISHED GE REVOLUTION ASPIRE 16/32 CT MACHINE

- REFURBISHED GE OPTIMA 520 16/32 CT MACHINE

- REFURBISHED GE HISPEED LXI/FXI/DXI (SINGLE) NXI (DUAL) CT MACHINE

- REFURBISHED GE OPTIMA 520 16/32 CT MACHINE

- REFURBISHED GE BRIVO 325 DUAL CT MACHINE

- REFURBISHED GE BRIVO 385 16/32 CT MACHINE

- REFURBISHED GE BRIGHT SPEED 4/8/16/32 CT MACHINE

- REFURBISHED CE CT/E HI SPEED DUAL CT MACHINE

- REFURBISHED CE CT/E HI SPEED DUAL CT MACHINE

- REFURBISHED GE VCT 64/128 CT MACHINE

- REFURBISHED GE LIGHT SPEED 4/8/16 CT MACHINE

- Refurbished GE Signa Creator 1.5T

- REFURBISHED GE REVOLUTION ACT 4/8/16 CT MACHINE

- REFURBISHED GE OPTIMA 540 16/32 CT MACHINE

- Refurbished GE Optima 450 1.5T

- REFRBISHED GE OPTIMA 660 64/128 CT MACHINE 4/128 Slice CT Machine

- Refurbished GE Signa Explorer 1.5T MRI Machine

- Syringe Pump

- Vein Viewer

- EVENT BANDS

- PRP TUBES

- RADIATION PROTECTION APPARELS

- Radiation Protection Patient Apron

- Thyroid Shield Universal

- Radiation Protection Coat Apron Large

- RADIATION PROTECTION APPARELS

- Radiation Protection Aprons Gonad Shield

- Radiation Protection Apron Vest Small

- Radiation Protection Apron Vest Medium

- Radiation Protection Apron Vest Large

- Radiation Protection Apron Vest Extra Large

- Radiation Protection Apron Vest Double Extra Large

- Radiation Protection Apron Skirt Small

- Radiation Protection Apron Skirt Medium

- Radiation Protection Apron Skirt Large

- Radiation Protection Apron Skirt Extra Large

- Radiation Protection Apron Skirt Double Extra Large

- Radiation Protection Double Sided Apron Small

- Radiation Protection Double Sided Apron Medium

- Radiation Protection Double Sided Apron Large

- Radiation Protection Double Sided Apron Extra Large

- Radiation Protection Double Sided Apron Double Extra Large

- Radiation Protection Head Shield Apron

- Thyroid Shield Sleek

- Thyroid Shield Reversible Universal

- Thyroid Shield Reversible Sleek

- Radiation Protection Head Shield Apron Lead-free

- Radiation Protection Coat Apron Small

- Radiation Protection Coat Apron Medium

- Radiation Protection Coat Apron Extra Large

- Radiation Protection Coat Apron Double Extra Lagre

- Radiation Protection Coat Apron XXL

- Radiation Protection Patient Apron Small

- Radiation Protection Patient Apron Medium

- Radiation Protection Patient Shield Small

- Radiation Protection Patient Shield Medium

- Radiation Protection Patient Shield Large

- Aluminium Granule

- Led X-Ray Viewer

- Contact Us

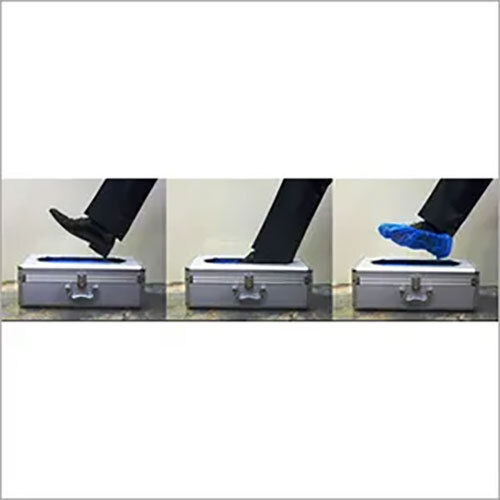

Automatic Shoe Lamination Machine

100000.00 INR/Piece

Product Details:

- Equipment Type Automatic Shoe Lamination Machine

- Material Steel

- Condition New

- Portable Yes

- Use Hospital

- Color Black

- Click to view more

X

Automatic Shoe Lamination Machine Price And Quantity

- 1 Piece

- 100000.00 INR/Piece

Automatic Shoe Lamination Machine Product Specifications

- Hospital

- Automatic Shoe Lamination Machine

- Yes

- New

- Black

- Steel

Automatic Shoe Lamination Machine Trade Information

- 100 Piece Per Week

- 7 Days

Product Description

Automatic shoe lamination machine is a type of industrial equipment used in the shoe manufacturing industry to apply a protective film or layer to the surface of a shoe. This machine is designed to automate the process of laminating or coating shoes, making it faster and more efficient.The machine typically consists of a conveyor system that feeds shoes through the laminating process, a vacuum suction system that holds the shoes in place during lamination, and a roller or press system that applies the protective film or layer to the shoes surface. The process starts with the operator loading the shoes onto the conveyor, and the machine takes over from there. The shoes are then fed through the laminating process, which can include cleaning, priming, and laminating. Automatic shoe lamination machine is made for automating the laminating or glueing of various layers of materials to create a shoe upper. Lamination of many layers of materials, such as leather, fabric, or synthetic materials, is a common method used to bind an upper to a sole or midsole of shoes. A conveyor belt system that transports the shoe upper through the machine and a number of rollers that apply pressure and heat to join the various layers of material together make up an automatic shoe lamination machine. A vacuum table that aids in keeping the materials in place when laminating may also be included in the machine.FAQs of Automatic Shoe Lamination Machine:

Q: What materials are used to construct the Automatic Shoe Lamination Machine?

A: The Automatic Shoe Lamination Machine is made of steel, ensuring durability and reliability.Q: Is the machine portable?

A: Yes, the Automatic Shoe Lamination Machine is designed to be portable for ease of movement and use.Q: What type of equipment is this?

A: This is an Automatic Shoe Lamination Machine.Q: What is the intended use of the machine?

A: The Automatic Shoe Lamination Machine is specifically designed for use in hospitals.Q: What is the condition of the machine when purchased?

A: The machine is available in new condition.Q: What color is the machine?

A: The Automatic Shoe Lamination Machine comes in black color.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email